Netra VS6

Netra VS6 is FDA ‘21 CFR part 11’ compliant.

Catch manufacturing defects that even the most experienced and sharpest of eyes cannot pick up, and at a speed that a human brain cannot process. Add to it the end-to-end efficiency, repeated application of learning on new batches, analyses, a seamless coupling for your manufacturing process – and you have a huge force multiplier in your hands. The generated reports that capture the results and attributes contribute to valuable learnings and course setting – an objective and analytical advantage of Netra VS6 over conventional eye inspection. No wonder it is called Netra, a Sanskrit word for the eye – to guide, conduct, and miss nothing.

The 6-camera vision system

6 industrial vision cameras inspect every 100 micron of every tablet, compositing a 360 degree view in milliseconds. A few salient features define the Netra VS6 vision system

- Servo motors that help the precise adjustments of camera focal length.

- Well-managed cabling and internal fastenings to maintain connection integrity.

- Inbuilt, high intensity light source for optimal illumination of the inspection zone, for the cameras.

- The high-resolution depth of each camera sensor and the computing electronic brain handling the image data feed, constitutes a high-speed intelligent system more efficient than human intervention.

High Speed Tablet Inspection

The use of high speed image capture and image processing technology allows Netra VS6 to evaluate each 100 micron of each tablet for up to 8 defects, at an astonishing speed of around 1,00,000 tablets /hour (depending on product size).

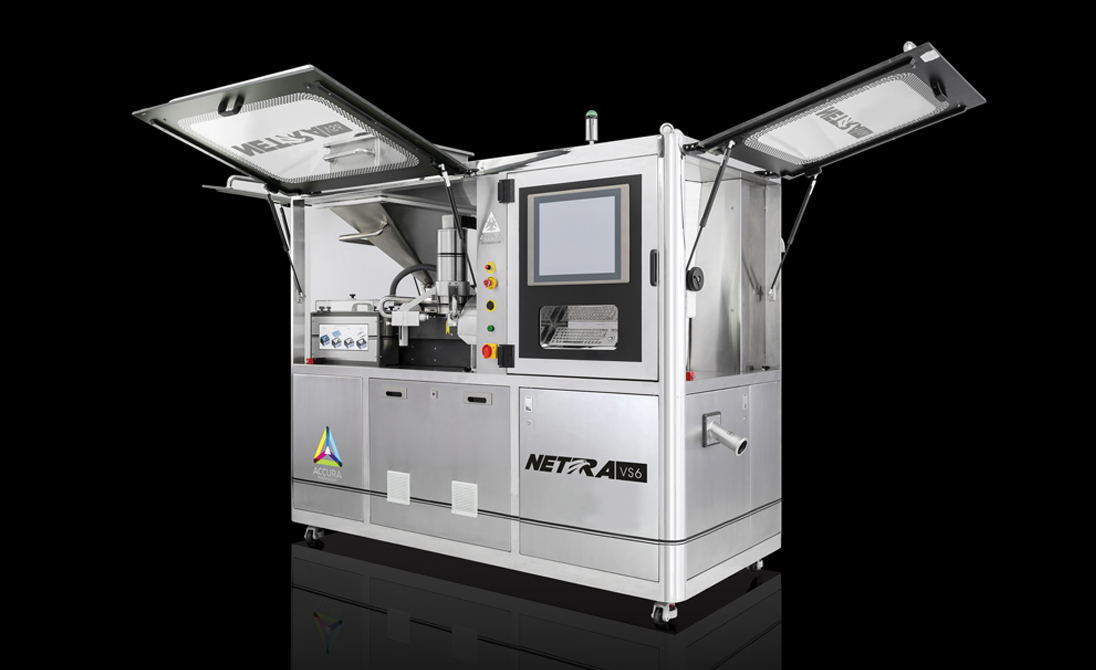

Build

Netra VS6 is built to conform to global regulations in pharmaceutical industry, and last long. The body and all the non-contact parts are made of S.S.304 (heat-resistant, corrosion-resistant, and suitable to industrial environments), with product contact parts in S.S.316 / FDA approved food-grade material. Dimensions: 2620 mm (w) x 1180 mm (d) x 2250 mm (h). Weight: 950 kg.

Conveyors

Conveyors I and II are designed with an internal vacuum underlay, which holds the product in place. They are Servo-operated for movement precision of the product along the inspection zone. The second conveyor is built for automatic, intelligent height-adjustments according to the thickness of the product. Human intervention is thereby rendered redundant.

Rejection Mechanisms

The rejection ports are located along the inspection conveyors and operate pneumatically with compressed air pressure. The rejected material travels down chutes to a collection bin.

Change Parts

The change part is a product-specific requirement. The selection depends on the width or the diameter of the product. It is exceedingly simple to replace – without the use of any tools, simply by loosening and tightening of four knobs by hand.

Reporting

Automatic and minute reporting increases integrity and efficiency of operation for pharmaceutical industry and it is a vital feature of Netra VS6. The record of every run is maintained by four types of reports — Batch Inspection, Audit Trail, Alarm, Parameter Setting, and Batch Trend. All these reports are indelible to prevent tampering or suppression of any event information.

The Batch Inspection report is the most significant, wherein the data carries a permanent record of the product name, product code, batch number, user ID, batch quantity, and the name of the personnel who prints out the report of the completed batch. Respective records of passed / failed product by each camera, and a record of the total batch are obtained. Pie charts featuring each defect displayed for every rejected product, are shown.

The Audit Trail report makes a record of every event, date, time, and stamping of each batch. The Alarm report keeps data of every alarm in a run, if any. The Parameter Setting report maintains records of all the parameters set before a run. And the Batch Trend report presents saved information of the likelihood of a defect occurring by which the product tends to get rejected.

Copyright by @ Earth Tekniks. All Rights Reserved