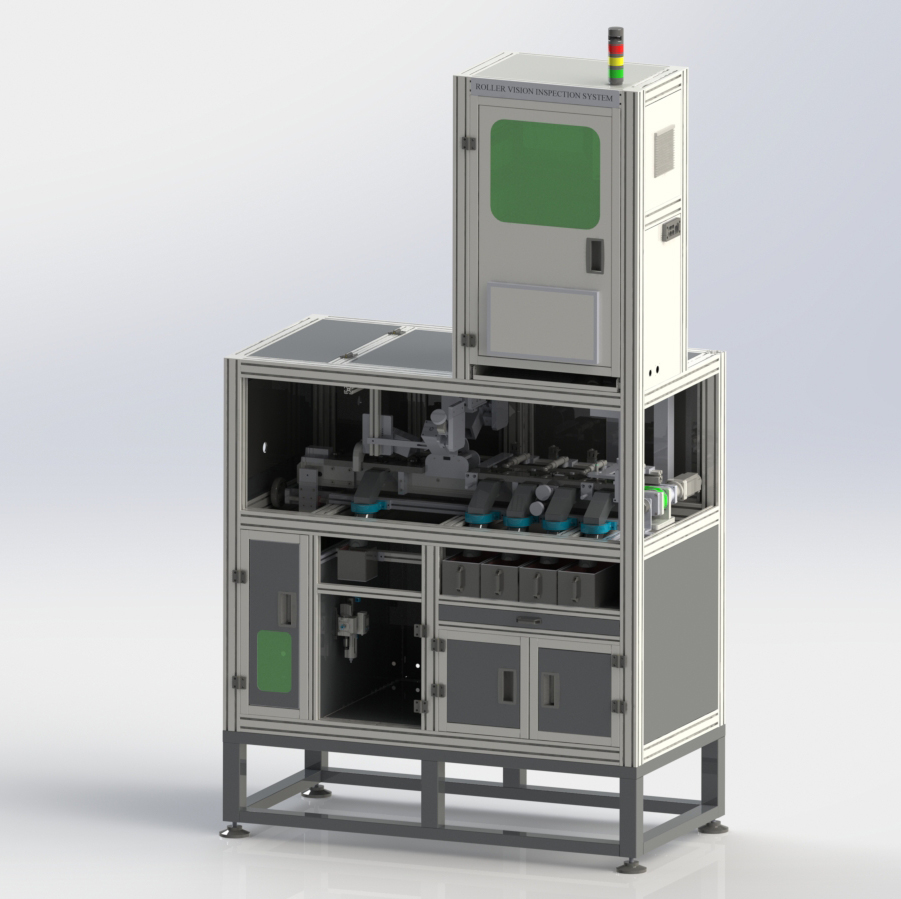

Roller Bearing Defect Identification Systems

Roller Bearing Defect Identification Systems:

In the manufacturing industry, ensuring the reliability and performance of roller bearings is of utmost importance. To meet stringent quality standards, a comprehensive roller bearing inspection system has emerged as a game-changer. Incorporating a four-camera system for 270-degree inspection, tunnel lighting for precise analysis, and efficient sorting mechanisms, this innovative solution enables manufacturers to achieve unparalleled quality control. The key features include : Superior Quality Control: The roller bearing inspection system employs advanced camera technology, precise lighting, and efficient sorting mechanisms to significantly enhance defect detection and analysis. This ensures that only high-quality roller bearings reach the market, reducing the risk of faulty products and enhancing customer satisfaction.

Enhanced Efficiency: With its four-camera system providing 270-degree inspection coverage, the roller bearing inspection system optimizes the inspection process, enabling rapid and comprehensive analysis. This leads to improved inspection throughput and reduced inspection cycle time, ultimately boosting overall operational efficiency.

Cost Reduction: By detecting defects early in the production process, the inspection system minimizes material waste, lowers rework costs, and helps prevent potential product recalls. This translates into significant cost savings for manufacturers while maintaining product integrity.

Regulatory Compliance Assurance: Roller bearings are subject to stringent quality standards mandated by regulatory bodies. By integrating the inspection system, manufacturers can ensure compliance with these regulations, mitigating the risk of penalties or legal complications that may arise from non-compliant products.

Real-time Data Logging and Error Notifications: The roller bearing inspection system offers real-time logging capabilities, allowing for comprehensive data collection and analysis. Additionally, the system provides error screens and instant notifications to operators, enabling prompt action in response to detected deviations or abnormalities. This proactive approach minimizes downtime, optimizes efficiency, and facilitates effective quality control management.

Seamless Integration with Existing Lines: Designed for easy integration, the roller bearing inspection system can be seamlessly incorporated into existing manufacturing lines. Whether used as a standalone unit or integrated into a larger automated system, its adaptability ensures a smooth transition without disrupting ongoing production processes.

- 4-camera system for 270-degree component detection

- Rugged and durable design for harsh environments

- Customized illumination unit to minimize reflections

- Easy-to-use software with real-time monitoring, advanced data logging, and error display

- Highly customizable settings for optimal performance

- Safety features such as fail-safes and emergency stop buttons

- Seamless integration with existing production lines

- Detailed reporting for troubleshooting and maintenance

- Error display feature on the software screen for easy identification of faults and troubleshooting

Copyright by @ Earth Tekniks. All Rights Reserved