Tipping Paper inspection in Cigarette

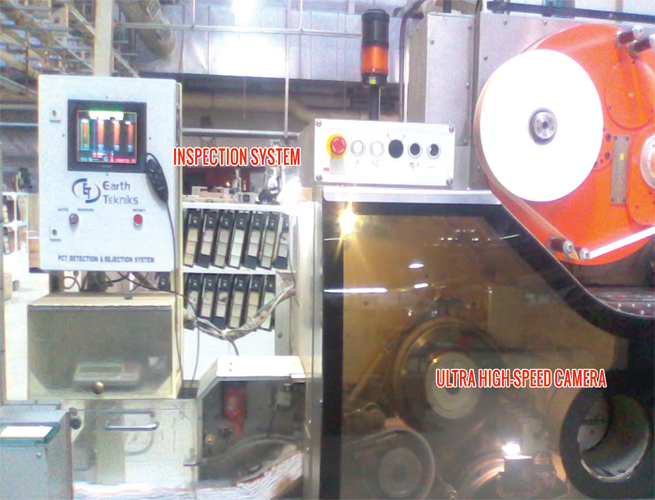

TPI Inspection System:

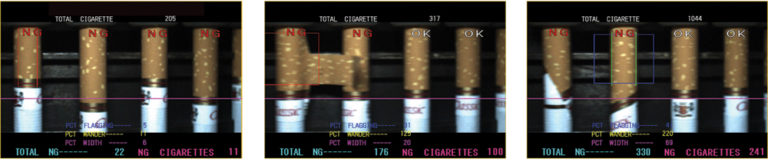

A trigger signal is input from an external device (fiber sensor, PLC, etc.) that activates the image capture of the vision system when the target is in front of the camera. At the instant of the trigger input, the camera captures a still image of the target according to the shutter speed. The High-Speed vision system outputs the results of the image processing to an external device. The most basic type of output result is the ON/OFF signal of the OK/NG judgment status, which is an NPN/PNP transistor type output. It is also possible to output the inspection results as numeric values through the I/O terminal, RS-232, and Ethernet. The result outputs that are received by the PLC or PC can be used to reject the defective product, activate alarms, control the movement of a robotic arm and control other automated processes.

PCT System has unique features to identify the defect and reject cigarettes having variations and deviations in the binding zone. Identifying defects are extremely important in the manufacturing process. The defects typically in the binding zone are due to Flagging of Filters, Wandering, Misalignment (axis ) of filter base with a top zone of cigarettes and Double batch. This system is a combination of high technology camera module and our hardware integration expertise and our reputation provides a new generation of cigarette rejection system. The automated vision-based defect system called the PCT Detection and Rejection System is customized and dedicated to identify and eliminate Non conforming cigarette with above said defects on a real-time basis, thus ensure defect-free products and reduces rejections.

System Description:

The System Compresses of the following:

- Panel having Display

- Software – Application of Specific Knowledge Based

- Functional Group Having Sensor Assembly and Rejecter.

Panel Display provides real-time indication and provides an output signal to rejecter assembly. The System software is knowledge-based and also can be customized to suit application/variations in the geometry/size of the cigarette. The software can be expanded to suit the process/product variations. The Rejecter is working based on the output from the system. The input to the system is from the sensor mounted in the line.

Copyright by @ Earth Tekniks. All Rights Reserved